Case Study:

Integrated Bakery Resources

Integrated Bakery Expands Its Production Line While Remaining Lean Throughout

Integrated Bakery Resources (IBR) develops and blends proprietary mixes for bakery products. Headquartered in Lake Oswego, Oregon, the privately-held company focuses on breads, bagels and English muffins. IBR maintains about 70 active formulas, 95% of which were developed for customers in its own labs. Ingredients such as flours are sourced worldwide, and its customer base includes virtually every state. The company also supplies the international markets.

IBR entered the blended mixes market in 2003. To accommodate this capability, the company had purchased a manual blending system engineered and manufactured by Ingredient Masters, Inc., Cincinnati, Ohio. The IM manual blending system was designed to handle IBR’s projected capacity of 100,000 pounds per month, but IBR had been using it to handle up to 20,000 pounds of blended product per day.

Two years later, IBR planned yet another major uptick in production. The goal: a 250 percent increase from 20,000 pounds per day to 50,000 pounds per day.

There were several daunting caveats involved. There would be no change in the company’s single, five-day, split-shift operation, which did blending and mixing in the morning and bagging and packaging in the afternoon. Both crew size (three workers on the blend line, three on the pack line) and total manhours would remain the same. The 30-day raw materials inventories standard would not change. And, with floor space at a premium, only a slight increase in total system footprint could be accommodated.

The mixes developed by IBR have up to 15 ingredients: ten “majors” and up to five “micros” — more than the industry norm. Even more significantly, the number of different ingredients used in all recipes totals more than 100. The inherent complexity of the blends presented special challenges to production.

Integrated Bakery Director of Operations Mike Lengacher once again consulted with Ingredient Masters, and learned that an automated system — originally built for one of the world’s leading pharmaceutical companies which had a change in plant requirements — would soon be available and could be adapted to IBR’s specifications.

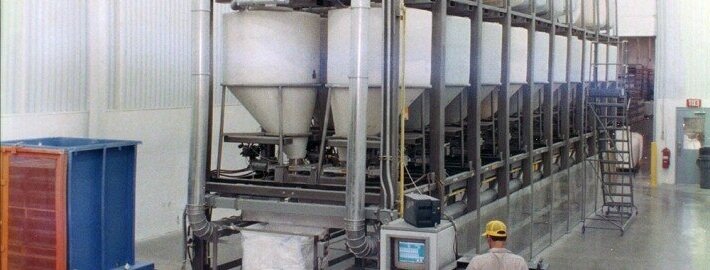

The system Ingredient Masters re-engineered and adapted for Integrated Bakery uses 16 free-standing bulk bag unloaders, 16 bag-lifting frames, 16 receiving hoppers and a robotic cart equipped with a gain-inweight scale system. System modules are computer-controlled; electric eyes ensure the cart stops where the recipe specifies. Twelve of the 16 units were part of the pharmaceutical system; four units were added. All surfaces that contact ingredients are USDA polyethylene or 304 stainless steel. Ingredient dispensers are configured in two rows of eight. Although only one dispenser is activated at a time, the dual rows, accessed alternatively, minimize processing time and space requirements. A batch bag is mounted on the robotic cart, which moves between the rows, stopping, filling and advancing to the next station according to process recipe. These batch bags, essentially a hybrid “super sack,” are distinct in that they have rigid sides and can be cleaned with an air-hose and reused.

Two thousand-pound bulk bags brought in from suppliers are also used to charge the ingredient dispensers used to create the batch. They are, for several reasons, more efficient than the 50-pound palleted bags used as an industry standard in the past. For example, since batches rarely require any ingredient in increments of exactly 50 pounds, an operator had been responsible for manually breaking the bags and weighing the material to achieve the specified total. According to Lengacher, the savings in time between manually breaking the bags, measuring the material and verifying its weight and simply suspending bulk bags in the frame, is significant — as is the ergonomic benefit realized by eliminating manual handling and potential injuries.

There are environmental and housekeeping benefits as well. There are no longer truckloads of empty paper bags being hauled to the dump, and yields are higher due to lack of breakage and hang-ups in individual paper bags. A dust collection system is ducted to each of the 16 stations and computerized valves control pickups at each station, so dust is collected at the source and clean-up is simplified.

Controls were specified and configured by IM Senior Lead Systems Engineer, Peter Hohorst, who installed Rockwell’s RSView with graphic interface onto a PC-driven PLC and created the ladder logic. Pairing the PLC’s instant communications with the PC’s archiving capacity gave the system exceptional accuracy and speed and virtually unlimited recipe storage.

Each hopper has an icon indicating the weight of the powder inside; visual alarms activate when replenishment is needed. At the start of the cycle, the system checks hopper content to ensure there’s sufficient raw material and will not permit the cycle to start if any material is not in adequate supply.

Entering a new job number (the recipe code, plus the number of times to run it) automatically generates a list for the operator of the “micro” ingredients that are not part of the 16 “major” ingredients held in the bulk bags. These three or four ingredients have a combined weight of less than ten pounds and are weighed and bagged manually. This ingredient package is added to the hopper when automatic batching is complete. Thus, while the automatic batching is underway, the operator can weigh these “minors.” Previously, operators did these tasks sequentially. Because they are now simultaneous, the time has been reduced by about half.

Ingredient codes are displayed on the operator screen; the color of the names changes if the active recipe calls for that ingredient. The station box changes to white if the station is inactive for that batch. When a station valve opens, the color of the valve icon changes on the screen. The net batch weight is indicated as a bar graph. Operators can adjust valve opening positions and activate flow-assist devices if needed.

The PLC controls the motion of the cart, monitors bin levels, and closely manages ingredient weights (IBR maintains +.2 lb. scale accuracy on each ingredient — tighter than the industry standard). The system also generates a report detailing what was scaled, the formulas used, and any variances. Programming and controls integration was provided by Ingredient Masters as part of the installation package.

IBR achieved its 250% production increase and, according to Lengacher, has also reduced its reliance on outsourcing. In 2005, Integrated Bakery Resources will move into a new plant in eastern Oregon and undergo another expansion. The modular design of the IM system will make at least that aspect of the move very straightforward.

“Sales are increasing,” says Lengacher, “helped in part by our ability to go from product concept to product-on-the-market in 30 days, if the customer circumstances are right.”

There are also important new national programs in the works, both traditional and low-carb.

“The difference between our low-carb and products that taste low carb…is ingredients,” says Lengacher. “We think we know how to source them — and blend them — better than anyone.”

As seen in Processing Magazine March 2005.